Mid-volume PCB assembly refers to manufacturing quantities that fall between prototype runs and full mass production. These orders generally range from a few hundred to several thousand units, making them ideal for growing companies, product testing phases, and specialized electronic applications. Mid-volume assembly is an essential bridge in the product lifecycle because it offers an optimal balance of speed, quality, and affordability.

For many businesses, mid-volume PCB assembly is the stage where a product transitions from concept validation to commercial success. It allows electronics manufacturers to scale gradually, test market demand, refine product performance, and optimize costs without committing to huge production runs. From consumer electronics to industrial automation to medical devices, mid-volume quantities support the increasing need for reliable, flexible, and scalable manufacturing.

Why Mid-Volume PCB Assembly Matters

Choosing mid-volume assembly offers multiple advantages that directly impact cost, efficiency, and product performance. It helps companies maintain stable supply levels without overproducing, which is extremely useful for products with fluctuating demand. Additionally, mid-volume builds enable manufacturers to evaluate long-term durability and functionality in real-world scenarios before scaling to mass production.

This stage is also crucial for risk reduction. By running mid-volume batches, engineering teams can identify minor usability flaws, component placement issues, thermal concerns, or signal integrity problems that were not visible during prototype testing. Fixing these issues early makes the final design far more robust.

Key Characteristics of Mid-Volume PCB Assembly

Balanced Production Speed

Mid-volume assembly is designed for efficiency without compromising accuracy. With optimized workflow management, automated SMT lines, and controlled quality checks, manufacturers can produce hundreds or thousands of boards quickly while maintaining high standards.

Cost Optimization Through Smart Material Sourcing

At mid-volume levels, manufacturers can negotiate better pricing for components and raw materials. This reduces unit cost significantly compared to prototype quantities. It also ensures steady component availability, which helps avoid delays caused by supply chain fluctuations.

Higher Focus on Quality Control

Although mid-volume quantities are larger than prototypes, they still allow ample time for detailed inspections. AOI, X-ray analysis for BGAs, ICT testing, and functional testing are commonly used to guarantee that the boards meet design specifications. Quality remains consistently high because error margins must stay minimal before proceeding to mass production.

The Mid-Volume PCB Assembly Process

Engineering Review and DFM Analysis

The process begins with a detailed engineering review, where the design files undergo DFM (Design for Manufacturability) checks. Even minor adjustments in trace width, solder mask clearance, or component orientation can improve production efficiency and reduce failure rates.

Material Procurement

Component sourcing for mid-volume builds is structured, timely, and cost-efficient. Manufacturers secure materials in advance, verify component authenticity, and prepare storage conditions that maintain reliability during assembly.

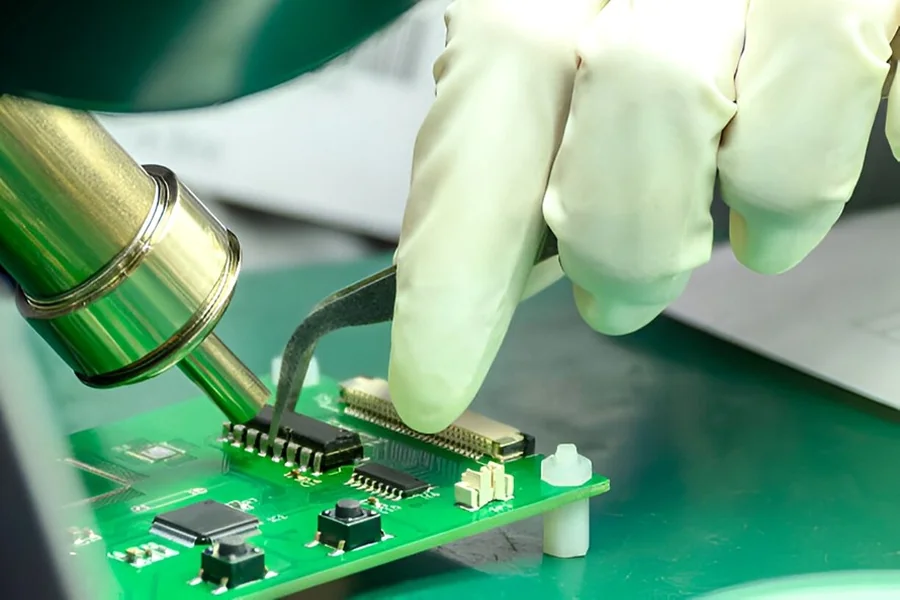

Automated SMT Assembly

SMT assembly is performed using high-speed pick-and-place machines capable of placing thousands of components per hour. Automated systems ensure precise alignment of ICs, passives, and connectors. Since mid-volume runs require consistency across all units, automation is essential for maintaining accuracy.

Reflow Soldering

After placement, the boards go through a reflow oven with a carefully controlled temperature curve. This ensures strong solder joints and prevents issues like tombstoning or cold joints. The consistency of reflow profiles is especially important in mid-volume PCB assembly, where every board must match the same quality standard.

Through-Hole Assembly

If the design includes through-hole components, they are assembled via selective soldering or wave soldering. Mid-volume orders benefit from automated through-hole soldering methods, which speed up the process while maintaining reliability.

Inspection and Testing

Inspection is one of the most critical stages in mid-volume PCB assembly. Manufacturers carry out:

- AOI (Automated Optical Inspection)

- X-ray inspection (for BGAs or hidden joints)

- ICT or flying probe tests

- Functional circuit tests

These procedures ensure that each board performs identically and meets all electrical, mechanical, and thermal requirements.

Advantages of Mid-Volume PCB Assembly

Scalability Without High Risk

Mid-volume assembly allows companies to scale their production gradually. This ensures that product demand, design performance, and supply chain readiness are all aligned before moving to mass production.

Cost Efficiency at Moderate Quantities

Mid-volume production reduces per-unit manufacturing costs due to bulk component sourcing and optimized assembly workflows. This makes it ideal for startups and growing businesses.

Shorter Lead Times

With automated equipment and well-planned workflow management, manufacturers can complete mid-volume batches faster than low-volume builds while maintaining consistent quality.

Better Flexibility for Product Improvements

Mid-volume production leaves enough room for design adjustments or minor upgrades before committing to large orders. This flexibility is extremely valuable in competitive electronic markets.

Industries That Benefit Most From Mid-Volume PCB Assembly

Several industries rely on mid-volume PCB assembly because it supports both innovation and scalability. Consumer electronics companies use it to prepare for mass-market launches. Industrial automation companies rely on mid-volume quantities to maintain steady supply for specialized equipment. Medical and automotive sectors use it to test and refine devices under rigorous performance conditions. IoT, aerospace, and telecommunications companies also depend heavily on mid-volume production to meet testing, certification, and market rollout phases.

Final Thoughts: Scale Your Production Smoothly With the Right Partner

Mid-volume PCB assembly is the ideal solution for manufacturers who need a perfect balance between prototype flexibility and high-volume cost efficiency. It ensures consistent quality, better cost management, and reliable performance across every board. If you are looking to scale your electronics production with confidence, partnering with an experienced and trusted manufacturer is the key. For dependable mid-volume PCB assembly with professional engineering support and fast turnaround, China PCBA is the best choice to help you move your product from development to market success.